G.Weike LF60MS

G.Weike LF60MS

THREE CHUCK ZERO REMAINS LASER CUTTING MACHINE

"0" Tail material

Professional three-chuck configuration,full-stroke clamping,one machine can cut,open holes,cut arcs,hollow out,wear through, which greatly saves the cost of raw materials

Fractional Automatic Support Installation

It employs intelligent tube support design,which can solve the deformation problems in the process of long tube cutting.

Full-automatic feeding and unloading material device

Automatic Feeding

Realize the intelligent material separation, feeding and seamless docking with the fiber laser cutting machine after the whole bundles of tubes are placed in the feeding device, and ensure that only one tube is delivered to the conveying arm each time.

Automatic Unloading

Clamp Design

It adopts an pneumatic clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-300mm.

Industry Applications

Take the oil industry for example, the main route of oil transport is the pipeline, and because of the characteristics of the oil itself, leading to the high quality requirements of the pipeline. While fiber laser cutting machine can achieve the pipes multi-angle precision processing to fulfil the oil transportation requirement. Professional tube fiber laser cutting machine—LF60M is used for cutting square tube, rectangular tube, oval tube, waist type tube, hexagonal tube; square tube □ 20 * 20- □150 *150mm, round tube Φ20-Φ 210mm wall thickness of 0.5-10mm carbon steel tube, 0.5-10mm stainless steel tube.

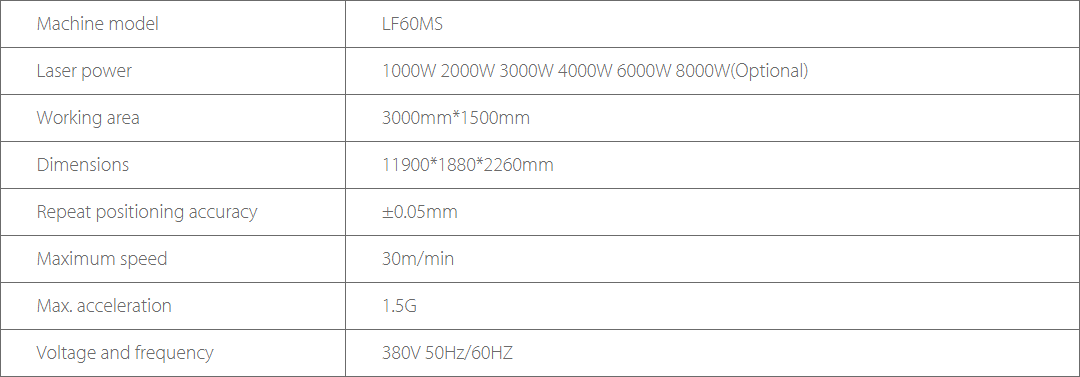

Technical Parameters