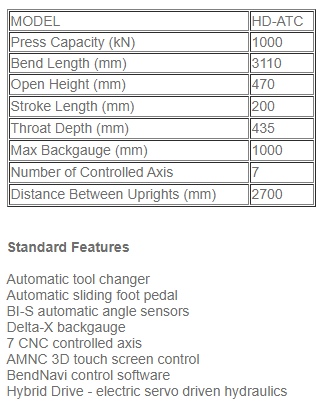

HD-ATC

HD-ATC

For OEM's and sub-contractors alike, increasing productivity and through-put is the main target for improving profitability. Smaller batch sizes are causing more time lost due to an ever increasing number of machine set ups. Amada's HD1003 ATC is the solution, allowing fast efficient set up when dealing with smaller batch sizes.

- Automatic Tool Changer - Ideal for small batch production

- Hybrid Drive System - ecological & high accuracy

- ‘Automatic Reactive' beam - world patented

- Digital part processing - BendNavi 3D control software

- BI-S automatic angle measuring system

Benefits

Automatic Tool Changing

- Amada ATC unit - automatic changing of 18 punches and 15 dies

- Automatic Hydraulic Tool Clamping

- Amada AMTSII Tool System

Reduced Power & Maintenance

- Hybrid Drive - Electric servo driven hydraulics

- 50% power saving

- 60% less oil

High Precision Operation

- Consistent angle accuracy

- Patented ‘Automatic Reactive’ beam

- High precision-5 Microns

Faster Part Processing

- BendNavi control software

- Input DXF/DWG/IGES files direct to control

Easy Operation

- Multi CNC controlled axis

- AMNC 3D touch screen control

Bending Solution Pack

- Delta-X backgauge

- Automatic sliding foot pedal

BI-S Automatic Angle Sensors

- Right first time